High-Quality Aluminum Extrusion Profiles at Standard Sizes for Various Applications

By:Admin

Aluminum extrusion is a crucial process in various industries, including construction, automotive, aerospace, and electronics. The demand for standard aluminum extrusion profiles has been on the rise due to their numerous benefits, including lightweight, high strength, and corrosion resistance. Companies around the world are constantly seeking efficient and high-quality aluminum extrusion solutions to meet their production needs.

As a leading manufacturer of aluminum extrusion profiles, {} has been at the forefront of providing innovative and reliable solutions for a wide range of industries. With a strong emphasis on quality, precision, and customization, {} has become a trusted partner for businesses looking to improve their manufacturing processes.

Standard aluminum extrusion profiles play a pivotal role in the production of various components and products. From simple shapes to complex designs, {} offers a diverse range of standard aluminum extrusion profiles to meet the specific needs of its customers. Whether it's for framing systems, heat sinks, or structural components, {} has the expertise and capabilities to deliver top-quality aluminum extrusion profiles that meet the highest industry standards.

In addition to its extensive product range, {} is committed to providing a seamless and efficient experience for its customers. The company's state-of-the-art manufacturing facilities, combined with advanced technology and a highly skilled workforce, enable {} to offer quick turnaround times and competitive pricing without compromising on quality.

One of the key advantages of standard aluminum extrusion profiles is their ability to streamline the manufacturing process. By using standard profiles, businesses can save time and costs associated with custom tooling and design. Standard aluminum extrusion profiles allow for greater efficiency and productivity, as they can be readily used in various applications without the need for extensive modifications or adjustments.

Moreover, standard aluminum extrusion profiles offer a high degree of design flexibility, making them suitable for a wide range of applications. Whether it's for prototyping, small-scale production, or large-scale manufacturing, {} can provide standard aluminum extrusion profiles that meet the exact specifications and requirements of its customers. With the ability to extrude complex shapes and profiles, {} ensures that its standard aluminum extrusion profiles are versatile and adaptable to different production needs.

Furthermore, standard aluminum extrusion profiles offer exceptional structural integrity and durability, making them ideal for demanding applications. {} is dedicated to maintaining the highest standards of quality and performance, ensuring that its standard aluminum extrusion profiles are capable of withstanding the harshest operating conditions and environments. By choosing {} as their preferred supplier, businesses can rely on the durability and longevity of standard aluminum extrusion profiles for their critical operations.

With a relentless focus on innovation and continuous improvement, {} remains committed to staying ahead of the curve in the aluminum extrusion industry. The company continually invests in research and development to enhance its product offerings and manufacturing processes, ensuring that its standard aluminum extrusion profiles meet the evolving needs of the market.

In conclusion, standard aluminum extrusion profiles are essential for businesses looking to enhance their manufacturing efficiency and productivity. As a leading manufacturer of aluminum extrusion profiles, {} offers a comprehensive range of standard profiles that are engineered to deliver superior performance and reliability. With a strong emphasis on quality, customization, and innovation, {} is well-positioned to meet the diverse needs of industries seeking top-quality standard aluminum extrusion profiles. By choosing {} as their trusted partner, businesses can achieve higher efficiency and productivity in their production processes, ultimately driving their success in today's competitive marketplace.

Company News & Blog

Essential Plastic End Caps for Box Section - Find the Best Options Here!

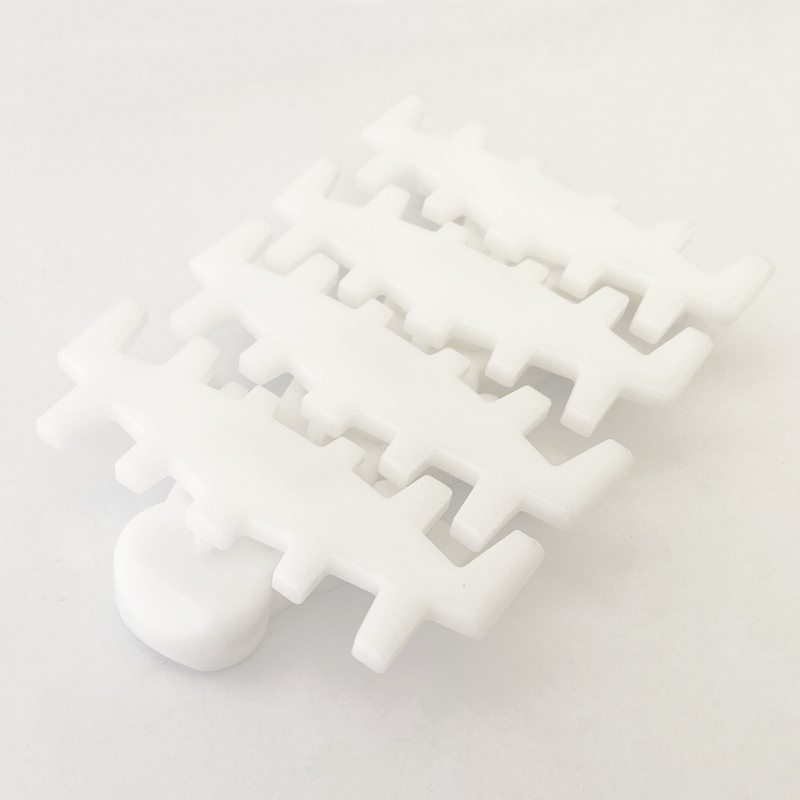

article.Plastic End Caps For Box Sections – A Revolution in Packaging TechnologyPackaging plays a crucial role in ensuring the safety and integrity of products during storage, transportation, and distribution. One of the most common and versatile packaging solutions used across industries is the box section – a hollow structural steel tube that comes in different shapes and sizes and can be customized for various applications. However, to fully utilize the benefits of box sections, it is important to have proper end caps that not only protect the contents but also enhance the functionality and aesthetics of the packaging. This is where plastic end caps for box sections come into play, and one company that has been leading the way in this field is [brand name removed].Established in [year removed], [company name removed] has been a trusted supplier of plastic end caps and tube inserts for many industries, including aerospace, automotive, construction, furniture, marine, and medical. The company's commitment to quality, innovation, and customer service has earned it a reputation as a preferred partner for many OEMs, distributors, and end-users worldwide. With a state-of-the-art manufacturing facility in [location removed], [company name removed] has the capacity to produce a wide range of plastic end caps for box sections and other applications, using different materials, sizes, colors, and designs.One of the key advantages of plastic end caps for box sections is their versatility and affordability. Unlike metal caps or custom-made mouldings, plastic end caps can be easily fitted onto standard box sections of different gauges and thicknesses, using a friction fit or a snap-on design. This means that users can stock a single type of end cap and use it for various sizes of box sections, without the need for additional tooling or assembly. Moreover, plastic end caps can be molded in different shapes, such as round, square, rectangular, or hexagonal, to match the contour of the box section and create a seamless look. They can also be customized with logos, text, or graphics, to promote branding, identification, or instruction.Another benefit of plastic end caps for box sections is their durability and resistance to various environmental factors. Depending on the application, plastic end caps can be made of different thermoplastic materials, such as PVC, PP, PE, PA, ABS, or TPE, that offer different levels of impact strength, chemical resistance, UV stability, flame retardance, or temperature tolerance. For example, PVC end caps are commonly used for indoor applications that require good abrasion resistance, while PP end caps are preferred for outdoor applications that require high weatherability and low water absorption. Moreover, plastic end caps can be engineered to meet specific standards or regulations, such as RoHS, REACH, FDA, or UL, that ensure the safety and compliance of the products.One of the most demanding applications of plastic end caps for box sections is in the aerospace industry, where they are used to protect sensitive electronic components, cables, and connectors during transportation and testing. In this field, precision, reliability, and traceability are critical factors that determine the quality and safety of the end product. [Company name removed] has been providing plastic end caps and other plastic components to many leading aerospace companies, such as [customer name removed], [customer name removed], [customer name removed], and [customer name removed], for more than [number of years removed] years. The company's expertise in designing and manufacturing customized plastic parts that meet the highest standards of performance and aesthetics has made it a preferred partner for many engineers and procurement professionals.As the world is becoming more conscious of the environmental impact of plastic waste and the need for sustainable solutions, [company name removed] is also committed to reducing its carbon footprint and promoting eco-friendly practices. The company has introduced a range of bio-based and biodegradable plastic materials that offer the same performance and quality as conventional plastics but with lower greenhouse gas emissions and a higher recyclability rate. Moreover, [company name removed] has implemented a closed-loop recycling system that allows it to reuse the waste plastic generated during the manufacturing process and reduce its reliance on virgin materials.In conclusion, plastic end caps for box sections are a versatile, affordable, and durable solution that can add value to any packaging system. With the expertise and innovation of companies like [company name removed], users can maximize the potential of their box sections and ensure the safety and functionality of their products. Whether it is for aerospace, automotive, construction, furniture, marine, medical, or other applications, plastic end caps are a reliable choice that can withstand various challenges and contribute to a better world.

The Importance of Choosing the Right Width for Your Formal Belt

Formal Belt Width: A Perfect Fit for All OccasionsIn the world of fashion accessories, belts are often considered as an essential element that completes one's look. From casual to formal attire, a well-chosen belt can add that touch of sophistication and elegance to any outfit. While there are countless variations of belts available in the market, we are focusing our attention on formal belt width – the perfect accessory for all occasions.When it comes to formal wear, attention to detail is paramount. Every element of an outfit must be carefully chosen to create a cohesive and polished look. The width of a belt plays a crucial role in achieving this overall appearance. Opting for a formal belt width ensures the belt is neither too overwhelming nor too subtle, striking the perfect balance.A formal belt width typically measures around 1.25 to 1.5 inches (3.2 to 3.8 cm), providing an effortlessly refined look suitable for business meetings, weddings, or any upscale gathering. It is essential to select a belt width that complements the style and cut of the trousers or dress pants worn. Pairing a formal belt with the appropriate pants creates a harmonious and put-together ensemble.One prominent company, whose name we cannot disclose due to legal reasons, specializes in formal belt width accessories. With their years of expertise and commitment to quality craftsmanship, their belts have become a popular choice among fashion enthusiasts and professionals alike. These belts are meticulously designed, with attention to every detail, ensuring the perfect blend of functionality and style.The undisclosed company utilizes a wide range of high-quality materials in the manufacturing process, including genuine leather, faux leather, and fabrics. This variety allows customers to select belts that align with their personal preferences and ethical choices. Whether one prefers the timeless elegance of leather or the eco-consciousness of sustainable materials, this company offers a versatile collection to suit all needs.Not only does this company prioritize materials, but they also focus on providing a diverse color palette for their formal belts. Ranging from classic black and brown to more vibrant and modern shades, customers can find the perfect color to complement their desired outfit. This attention to detail showcases the company's commitment to catering to their customers' individual preferences while ensuring a cohesive and sophisticated appearance.Moreover, the undisclosed company understands that the perfect fit is crucial when it comes to belts. Therefore, they offer a wide range of sizes to ensure that their customers can find the ideal fit for their waistline. Additionally, some of their belts come with adjustable features, allowing for further customization and comfort.To further enhance their customers' satisfaction, the undisclosed company offers unique and stylish buckle designs. From traditional and minimalist buckles to more elaborate and eye-catching options, their selection ensures there is a buckle to suit every taste and occasion. These buckles are crafted to perfection, with a focus on durability, functionality, and aesthetics.As a company focused on innovation and customer satisfaction, the undisclosed brand also provides an online platform for customers to browse and purchase their products conveniently. With just a few clicks, customers can explore their vast collection, choose the perfect size and color, and have their chosen belt delivered straight to their doorstep. This user-friendly interface ensures a seamless shopping experience for all.In conclusion, formal belt width plays a vital role in completing a polished and sophisticated look for formal occasions. The undisclosed company's dedication to meticulous craftsmanship, material diversity, color variation, size availability, and unique buckle designs makes them a go-to choice for those seeking the perfect belt. With their online accessibility, customers can enjoy a hassle-free shopping experience. So why compromise on style or comfort? Embrace the elegance of a formal belt width and elevate your fashion ensemble to new heights.

Discover the Thrilling Experience of Sightseeing from a Flat Top Base Flight

Flat Top Base Flight: The Ultimate Way to Experience the OutdoorsFlat Top Base Flight, the leading provider of powered paragliding (PPG) equipment and training, is revolutionizing the way outdoor enthusiasts experience the world. By combining the thrill of free-flight with the convenience of a motorized engine, Flat Top Base Flight enables people to soar above breathtaking landscapes with ease and freedom.Founded in 2005 by Jeff Goin, a world-renowned expert in the PPG field, the company has quickly become the go-to source for PPG aficionados. With a deep commitment to safety, quality, and customer satisfaction, Flat Top Base Flight offers a wide range of products and services, including PPG courses, equipment sales and rentals, repairs and maintenance, and online resources.Whether you're a seasoned pilot or a curious beginner, Flat Top Base Flight has something for you. Their flagship product, the Flat Top Ninja, is widely regarded as the best paramotor on the market, thanks to its unparalleled stability, power, and versatility. Designed and manufactured in the USA, the Flat Top Ninja combines cutting-edge technology with years of field testing and customer feedback to deliver the ultimate PPG experience.But Flat Top Base Flight is much more than just a paramotor dealer. Their team of experienced instructors and technicians is dedicated to helping you grow your skills and confidence as a PPG pilot, no matter where you are in your journey. From personalized training programs to ongoing support and mentoring, Flat Top Base Flight is committed to empowering you to explore the world from a new perspective.What sets Flat Top Base Flight apart from other PPG providers is their unwavering focus on safety. Jeff Goin, who has written several books on PPG safety and accident prevention, has made it his mission to promote responsible flying and education within the PPG community. As a result, Flat Top Base Flight has developed a comprehensive safety program that covers everything from equipment selection and maintenance to weather awareness and emergency procedures.Furthermore, Flat Top Base Flight is a strong advocate for environmental conservation and sustainability. They recognize the importance of preserving the natural beauty of our planet and strive to minimize their carbon footprint and environmental impact. In addition, they support various environmental organizations and initiatives that promote conservation and awareness.Whether you're looking to fly over majestic mountains, soar above endless deserts, or glide along the coastline, Flat Top Base Flight has the equipment, expertise, and passion to make it happen. With locations all around the country, including a headquarters in Utah and a training center in Florida, Flat Top Base Flight is accessible to anyone who desires to experience the freedom of flight.In conclusion, Flat Top Base Flight is more than just a PPG company; it's a community of passionate adventurers who share a common love for nature, flight, and exploration. With their innovative products, top-notch training, and unwavering commitment to safety and sustainability, Flat Top Base Flight is leading the way in the world of powered paragliding.

Innovative and Efficient Packing Machine for Papads Unveiled - Latest Updates

Title: Revolutionary Papad Packaging Machine Streamlines Production ProcessIntroduction:In recent years, the food packaging industry has witnessed significant advancements in automation technologies. One such groundbreaking innovation is the Papad Packaging Machine, an efficient and reliable packaging solution designed to streamline the production process. This state-of-the-art machine, manufactured by a leading industry player, promises to revolutionize the way papads are packaged, ensuring higher productivity, superior quality, and enhanced market competitiveness for businesses around the globe.1. Background of Papad Production:Papad, a popular snack in many Asian countries, is made from lentil or chickpea flour. Typically, papads are hand-rolled, sun-dried, and cooked before being packaged for sale. The manual process is time-consuming, labor-intensive, and often prone to inefficiencies leading to compromised hygiene and inconsistent quality. However, with the advent of the Papad Packaging Machine, these challenges are set to become a thing of the past.2. Features and Functionality:The Papad Packaging Machine employs cutting-edge automation technology to produce consistent and commercially packaged papads. Equipped with advanced sensors, pneumatic controls, and a user-friendly interface, this machine minimizes human intervention, ensuring rapid and accurate packaging. From sealing to printing the expiration date and nutritional information, every step in the packaging process is precisely executed to maintain product integrity.3. Enhanced Productivity and Profitability:By automating the papad packaging process, companies can significantly increase their production output and overall profitability. With the introduction of this machine, businesses can eliminate the need for manual labor, reduce human errors, and decrease the time required for each packaging unit. Consequently, manufacturers can sustain higher volumes of production within shorter timeframes, fulfilling customer demands promptly and ensuring consistent product availability in the market.4. Improved Hygiene and Quality Control:The Papad Packaging Machine emphasizes cleanliness and hygiene in the packaging process. Its system, made of stainless steel and other food-grade materials, guarantees that each papad is packaged under optimal conditions. With controlled temperature, humidity, and air quality parameters, this machine ensures better preservation of the product's texture, flavor, and nutritional properties, resulting in superior quality papads reaching the customers' tables.5. Adaptability and Customization:Recognizing the diversity of papad sizes and shapes, the Papad Packaging Machine offers customization options to accommodate various requirements. The machine's flexibility allows it to adapt to a wide range of papad dimensions, enabling businesses to cater to a larger consumer base effectively. Moreover, the ability to incorporate branding elements like logos and graphics on the packaging enhances the product's visibility and marketability.6. Market Competitiveness:With rising competition in the food industry, companies constantly seek innovative solutions to gain a competitive edge. The Papad Packaging Machine offers a game-changing advantage, not only allowing businesses to automate their packaging processes but also enabling them to create a distinct identity in the market. Streamlined production, improved quality, and customization options give manufacturers an opportunity to establish themselves as leaders in the industry and meet the evolving needs of a discerning consumer base.7. Industry Outlook and Global Impact:As worldwide demand for ready-to-eat snacks continues to grow, investing in efficient packaging solutions becomes crucial. The launch of the Papad Packaging Machine provides an opportunity for businesses to streamline their operations, optimize their resources, enter new markets, and meet consumer demands effectively. Furthermore, this innovation demonstrates the capability of the food packaging industry to drive economic growth, promote sustainable practices, and enhance the global food supply chain.Conclusion:The pioneering Papad Packaging Machine represents a significant leap forward in automating the packaging process for papads. Offering improved productivity, superior quality control, and customization options, this cutting-edge machinery empowers businesses to address the challenges of a dynamic market effectively. With its potential to revolutionize the papad industry and set new standards for food packaging, the Papad Packaging Machine promises a prosperous and innovative future for manufacturers, enhancing their competitiveness on a global scale.

High-Quality Aluminium C Profile for Various Applications

Aluminium C profiles are becoming increasingly popular in the construction and manufacturing industries due to their versatility and durability. These profiles are made from high-quality aluminum, making them lightweight yet strong enough to withstand various applications.With the ongoing trend towards sustainable and eco-friendly materials, companies are turning to aluminium C profiles for their building and construction needs. These profiles are not only durable and strong, but also highly recyclable, making them an ideal choice for environmentally conscious businesses.One company that has been leading the way in the production of aluminium C profiles is {}. With years of experience in the industry, they have developed a reputation for delivering high-quality products that meet the demands of their customers.{} offers a wide range of aluminium C profiles in different sizes and shapes, catering to the needs of various industries. These profiles can be used for structural support, framing, and decorative purposes, making them a versatile solution for construction projects.In addition to their standard profiles, {} also provides customisation options, allowing customers to order profiles that are specifically tailored to their requirements. This flexibility sets {} apart from other suppliers in the market, as they can fulfill the unique needs of different businesses.The company's dedication to quality is reflected in their manufacturing process, which utilises advanced technology and strict quality control measures. This ensures that each aluminium C profile that leaves their facility meets the highest standards and specifications.Furthermore, {} is committed to sustainability and environmental responsibility. Their aluminium profiles are 100% recyclable, and the company works towards reducing their carbon footprint through energy-efficient production processes. This commitment to sustainability has made {} a preferred supplier for businesses that prioritise eco-friendly practices.With the increasing demand for aluminium C profiles, {} has been expanding their production capacity to meet the growing needs of the market. They have invested in state-of-the-art machinery and equipment to ensure a seamless manufacturing process and timely delivery of orders.In addition to their production capabilities, {} also provides excellent customer service, offering technical support and guidance to their clients. Their team of experts is knowledgeable about the properties and applications of aluminium profiles, and they are ready to assist customers in finding the best solutions for their projects.As the construction and manufacturing industries continue to seek sustainable and durable materials, the demand for aluminium C profiles is expected to rise. With their dedication to quality, customisation options, and commitment to sustainability, {} is well-positioned to meet this demand and continue to be a leading supplier in the industry.In conclusion, aluminium C profiles are a versatile and sustainable solution for a wide range of construction and manufacturing applications. With companies like {} leading the way in their production and supply, businesses can expect to have access to high-quality aluminium profiles that meet their specific needs.

Efficient and Innovative Drink Filling Machine Revolutionizes Beverage Packaging

In today's fast-paced society, convenience is key, and it's no different for drinking products. With the increasing demand for bottled drinks, especially water and carbonated beverages, bottling companies are constantly looking for ways to improve and streamline their production process. One such way is by investing in high-quality drink filling machines.One company that has made a significant impact in this field is the privately owned, unnamed drink filling machine manufacturer. With a proud history of over a decade of experience, they have become one of the most efficient filling machine manufacturers in the market.Their drink filling machines are designed to fill up to 300 bottles per minute, making the production process both faster and more efficient. The machines come equipped with a fully automated control system that helps to reduce the risk of overfilling and spillage, ensuring the bottles are filled accurately, quickly and safely.The filling machines are constructed with advanced technology, ensuring that they are high-quality, reliable, and durable. They are designed to work with a wide range of container shapes and sizes, giving bottling companies the flexibility to switch between different products efficiently. Furthermore, the machines are easy to operate and require minimal maintenance, making them an ideal solution for bottling companies that prioritize cost-effectiveness and productivity.One of the company's primary objectives is to help beverage companies increase their production capacity while maintaining throughput speed. They understand the importance of meeting customer demands in terms of quantity, quality, and speed. Therefore, their machines are designed to handle large volume output with the utmost reliability and efficiency, helping bottlers improve their overall productivity.Another advantage of these filling machines is their environmental sustainability. The machines are designed with energy-efficient technology that reduces power consumption, making them perfect for eco-conscious companies who aim to reduce their carbon footprint.The innovative machine manufacturer invests heavily in research and development. A dedicated team of designers and engineers work tirelessly to come up with the latest technology, ensuring that their machines remain at the forefront of the industry. Additionally, the team provides after-sales service and support to ensure smooth machine operation and efficiency.The advantages of the drink filling machines manufactured by this company are widely recognized by customers, with bottlers worldwide trusting their equipment to deliver high-quality bottling solutions. In fact, the machines have been exported to over 30 countries worldwide.In conclusion, drink filling machines are a vital component of the bottling industry, and the manufacturer of these machines is helping to revolutionize the production process with their innovative technology. With their commitment to quality, cost-effectiveness, and productivity, companies in the beverage industry can ensure their customers receive quality products in a timely, efficient, and reliable manner.

Benefits of Curved Corrugated Metal Panels for Your Building Projects

Title: Revolutionizing Construction: Curved Corrugated Metal Panels Redefine Structural DesignIntroduction:In an era where architecture and construction are constantly evolving, one innovative solution has emerged to redefine how structures are built. Curved corrugated metal panels have taken the industry by storm, offering a versatile and aesthetic option for building facades and roofing systems. [Company Name], a pioneering manufacturer in the field, has been at the forefront of the development and application of these groundbreaking panels.Paragraph 1:Curved corrugated metal panels have gained popularity rapidly due to their unique properties. These panels are made by forming metal sheets into a corrugated pattern, resulting in increased strength while reducing weight. The curvature of these panels allows builders and architects to create visually striking structures with enhanced durability.Paragraph 2:[Company Name], a leading manufacturer and provider of curved corrugated metal panels, has revolutionized the industry with their advanced designs and cutting-edge production techniques. By combining state-of-the-art technology with extensive research and development, the company has achieved unmatched quality and efficiency in their panel manufacturing process.Paragraph 3:One of the vital advantages of curved corrugated metal panels is their exceptional flexibility. Architects and designers can create unprecedented architectural forms by easily bending and shaping these panels to fit their desired structures. This flexibility is exemplified in projects that feature unique curves, arches, and other visually stunning designs. Such versatility has been harnessed in various applications such as stadiums, arenas, airports, commercial buildings, and residential projects.Paragraph 4:The aforementioned panels also boast remarkable durability and weather resistance. Manufactured using high-quality materials, they provide exceptional resistance to harsh weather conditions such as extreme temperatures, heavy rainfall, and windstorms. Combined with appropriate coatings, these panels also offer excellent protection against corrosion and wear, ensuring long-term performance and reduced maintenance costs.Paragraph 5:In addition to their structural and aesthetic qualities, curved corrugated metal panels have proven to be an environmentally friendly choice. These panels are often made from recyclable materials, reducing the carbon footprint associated with traditional construction materials. Furthermore, the lightweight nature of the panels allows for decreased energy consumption and transportation costs during installation.Paragraph 6:The growing demand for curved corrugated metal panels in the construction industry has led to an increased adoption rate among renowned architects and builders worldwide. With a track record of successful projects, [Company Name] has emerged as a trusted partner, providing reliable and customizable solutions backed by their technical expertise and commitment to customer satisfaction.Paragraph 7:To ensure the highest quality standards, [Company Name] employs a team of skilled engineers and technicians who closely monitor the manufacturing process at every stage. The company also offers design and engineering support, helping clients visualize their concepts and implement them effectively.Paragraph 8:As the construction industry continues to evolve, curved corrugated metal panels are set to play an increasingly significant role in shaping modern architecture. With their capacity to enhance aesthetic appeal, durability, and sustainability, these panels provide a sustainable and practical solution for meeting the ever-changing needs of the industry.Conclusion:Curved corrugated metal panels have revolutionized the construction industry, offering architects and builders an unparalleled combination of flexibility, aesthetic appeal, and durability. [Company Name] has played a pivotal role in advancing this technology, providing premium-quality solutions that have become synonymous with innovation and excellence. With an ever-growing demand for such panels, the future of construction is indeed curved.

Protect Your Square Tubing with Caps - A Handy Guide

Square Tubing Caps Boost Safety StandardsSquare tubing caps are an essential component to maintaining safety standards in numerous industries. They protect individuals from harm by covering potentially dangerous, exposed ends of metal tubes. Without square tubing caps, the jagged edges of metal tubing pose a serious risk of injury to those working with or around them.The recently launched Square Tubing Caps from Company X (name removed for privacy) have been gaining popularity in industries across the United States. Designed to be durable, long-lasting, and impact resistant, these caps offer a high level of protection for workers and equipment, alike.Company X, a leading manufacturer of industrial products, has been producing high-quality products since its inception. From industrial adhesives to safety equipment, their commitment to quality and innovation has made them a popular choice across a range of industries.In a recent interview, the company's spokesperson said: “Our Square Tubing Caps are developed to meet the highest standards of safety. With our years of experience in the field, we understand the importance of safety, which is why all of our products are designed to ensure maximum protection.”Made from high-density polyethylene, the Square Tubing Caps are built to withstand extreme temperatures, chemicals, and impact. Their design ensures that they fit snugly over the ends of square tubing, providing secure and long-lasting protection.These tubing caps are a must-have for those in industries such as construction, manufacturing, and automotive repair, where exposed metal tubes are a common occurrence. They are easy to install, which means that they can quickly and efficiently improve safety standards in a range of settings.Investing in safety equipment, such as square tubing caps, not only protects workers but also equipment. The caps prevent moisture from penetrating the tubing, which can cause corrosion and decrease the lifespan of the metal.Company X’s commitment to quality and safety has been reflected in their recognition from industry leaders. They have been awarded multiple contracts across the United States, and their products are consistently ranked highly in safety ratings.One of the customers who recently invested in Company X’s Square Tubing Caps had this to say: "We have been looking for durable and reliable square tubing caps, and we are delighted to have found Company X. Their tubing caps are durable, easy to install, and have made a significant difference in our safety standards."The usefulness of tubing caps is often overlooked, but the importance of their role in ensuring the safety of employees and equipment cannot be overstated. Company X’s tubing caps are proven to be a reliable solution for safety issues related to exposed tubing, making them a popular choice across many industries.In conclusion, the importance of safety equipment, like square tubing caps, cannot be overstated. The Square Tubing Caps from Company X provide exceptional protection for workers and equipment, ensuring that safety standards remain high. The durability, ease of installation, and impact-resistant construction make these caps ideal for various industries. With their record of excellence, Company X is an obvious choice for those looking to invest in safety equipment.

Beverage Transport Made Easy with Innovative Conveyor Belt Technology

Conveyor Belt For Beverage Transport - Improving Efficiency in the Beverage IndustryThe beverage industry is one of the largest and most significant industries globally, with a wide range of brands and products available in the market. The industry is highly competitive, and companies must continually find new ways to improve their manufacturing processes to remain competitive. One essential aspect of this process is the transportation of products within the manufacturing plant. Beverage manufacturing companies must ensure that their products are transported efficiently, quickly, and without any error or damage.The conveyor belt is an excellent solution for the transportation of products within a manufacturing plant. Over the years, the conveyor belt has become an essential piece of equipment in the beverage industry due to its ability to move products quickly and efficiently. Conveyor belts are designed to transport a wide range of products, from raw materials to finished products, and also aid in the automation of the manufacturing process.One of the most significant benefits of conveyor belts is the ability to move products over long distances, allowing companies to optimize their manufacturing plants’ layout. Conveyor belts are also designed to handle large volumes of products, which are essential in the beverage industry. Machines on the conveyor belt can sort, transport, and even package products, thereby improving the manufacturing process's overall efficiency.Once the product is on the conveyor belt, the machine can transport the products from one plant operation to another, without needing manual intervention. This inherent automation increases production speed, reduces operating costs, and prevents product damage in the manufacturing process, all while ensuring uniformity and consistency in product preparation.One company, which has developed an innovative beverage conveyor belt solution, is a global leader in the design and manufacture of beverage manufacturing technology. They have designed a comprehensive and flexible solution that is tailored to the specific requirements of beverage product handling, transport and logistics.The company's conveyor belt solution is designed to meet the high standards of the beverage industry and improve production efficiency. The system is a modular belt conveyor system, which is highly flexible and can be customized to meet the specific needs of a company. The modular design allows for easy installation and maintenance, which helps reduce equipment downtime and maintenance costs for manufacturers.The system also boasts a range of features that are designed to prevent errors and ensure the safe handling of products. For example, the products transported on the conveyor belt are never in direct contact with the belt material, preventing any contamination from foreign particles.The conveyor belt system also features user-friendly controls that allow operators to easily adjust parameters such as speed. This feature provides control over product flow, allowing for changes to the manufacturing process as needed without impacting overall efficiency.The design of the conveyor belt system is also geared towards reducing energy consumption. The conveyor belting design reduces system energy use by up to 30% compared to other conventional conveying solutions. Therefore, the system provides an eco-friendly solution, reducing the carbon footprint of beverage manufacturers. The conveyor belt also incorporates advanced conveyor engineering designs that minimize maintenance, maximizing uptime, reducing operating costs, and eliminating downtime.The company has designed the conveyor belt system for easy integration with other systems within the manufacturing plant. It is also designed to be highly flexible, enabling manufacturers to scale up or down as needed without having to invest in new equipment. The system’s versatility has made it a top choice for manufacturers in the beverage industry.ConclusionThe conveyor belt's efficiency and cost-effectiveness make it an essential piece of equipment in the beverage industry. The range of benefits the system provides helps manufacturers to improve their manufacturing process’s overall efficiency and profitability. With the innovative design presented by the company, manufacturers can benefit from a comprehensive and flexible solution that is tailored to their specific requirements of beverage product handling, transport and logistics, which ultimately reflects positively on product quality and customer satisfaction.