How to Immediately Improve Plumbing with a Flush Grid

By:Admin

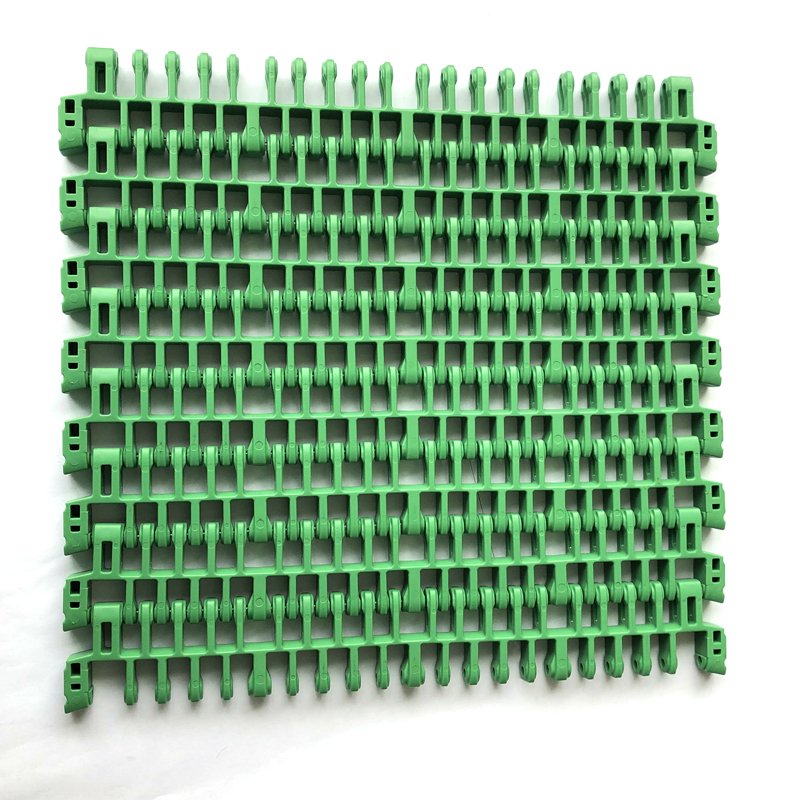

The company, with its headquarters in Los Angeles, has a state-of-the-art manufacturing facility equipped with the latest technology and machinery. This allows Flush Grid to produce a wide range of conveyor belts that meet the diverse needs of its customers. From modular plastic belts to tabletop chains, the company offers a comprehensive range of products that are designed to deliver optimal performance and efficiency.

One of Flush Grid's standout products is its modular plastic conveyor belts, which are known for their durability and versatility. These belts are designed to withstand tough operating conditions and are suitable for a wide range of applications, from transporting heavy loads to handling intricate processes in the food and beverage industry. Flush Grid's modular plastic belts are also easy to clean and maintain, making them an ideal choice for industries where hygiene and cleanliness are paramount.

In addition to its product range, Flush Grid also offers customization options to meet the specific needs of its customers. The company has a team of experienced engineers and technicians who work closely with clients to develop tailored solutions that address their unique requirements. This customer-centric approach has earned Flush Grid a reputation for delivering bespoke conveyor systems that enhance the efficiency and productivity of its clients' operations.

Flush Grid is also committed to sustainability and environmental responsibility. The company adheres to strict quality and safety standards in its manufacturing processes, ensuring that its products are not only reliable but also environmentally friendly. By using recyclable materials and optimizing its production processes, Flush Grid strives to minimize its impact on the environment and contribute to a more sustainable future.

One of the key factors contributing to Flush Grid's success is its dedication to research and development. The company invests heavily in innovation, continuously developing new technologies and processes to improve the performance of its conveyor systems. This relentless pursuit of excellence has allowed Flush Grid to stay ahead of the curve and offer its customers the latest advancements in conveyor belt technology.

Flush Grid's commitment to quality and customer satisfaction has earned it a loyal customer base and a strong reputation in the industry. The company has a global presence, serving clients in various countries and regions around the world. Its products are known for their reliability, durability, and performance, making Flush Grid a preferred choice for businesses looking for high-quality conveyor solutions.

As Flush Grid continues to expand its product range and reach new markets, the company remains focused on its core values of innovation, quality, and customer service. With a track record of success and a forward-thinking approach, Flush Grid is poised to maintain its position as a leader in the industrial conveyor systems industry for years to come.

Company News & Blog

Innovative New Tool Allows for Easy and Precise Adjustments of Head Position

Title: Groundbreaking Swivel Head Technology Revolutionizes Workplace ErgonomicsIntroduction: In a world where an increasing number of people spend long hours seated at their workstations, incorporating revolutionary ergonomic features into office furniture becomes paramount. Today, we bring you a game-changing innovation that aims to transform the way we work. The groundbreaking Swivel Head technology, developed by an industry-leading company, promises to enhance the ergonomic experience and improve overall health and productivity in the workplace.Paragraph 1: Explaining the Concept of Swivel Head TechnologySwivel Head technology is a remarkable advancement in ergonomic design that addresses the need for multi-directional flexibility in office furniture. With its innovative ball joint mechanism, this cutting-edge technology allows users to effortlessly rotate the headrest and backrest of their chairs into various positions, providing optimal support and conforming to the natural curvature of the spine.Paragraph 2: Promoting Healthy Posture and Reducing Back PainOne of the key advantages of the Swivel Head technology is its ability to promote healthy posture, thereby reducing the risk of back pain and related musculoskeletal disorders. By allowing users to adjust the chair based on their individual comfort preferences, the Swivel Head technology provides excellent lumbar support, leading to improved spinal alignment and reduced stress on the lower back.Paragraph 3: Customizable Ergonomics for Maximum ComfortThe Swivel Head technology ensures that every user can tailor their seating experience to their unique requirements. Whether it's angle-adjustable headrests or individually adaptable backrests, the technology offers a customizability that guarantees maximum comfort and support. With this level of personalization, employees can enjoy extended periods of work without experiencing discomfort or fatigue.Paragraph 4: Enhanced Productivity and ConcentrationNumerous studies have demonstrated that optimal ergonomic conditions can significantly improve concentration and productivity in the workplace. By incorporating Swivel Head technology into office chairs, employers can create an environment that reduces distractions and enables employees to focus on their tasks with enhanced comfort. The technology's adaptability ensures that employees can maintain their focus over prolonged periods, boosting overall efficiency and output.Paragraph 5: Diverse Applications in Different Work EnvironmentsSwivel Head technology is not limited to office chairs alone. The versatility of this innovative solution enables it to be integrated into a range of furniture, including conference room chairs, executive seating, and even collaborative spaces. Regardless of the work environment, Swivel Head technology enhances the overall comfort and well-being of employees, contributing to a more positive and productive work atmosphere.Paragraph 6: Environmental Sustainability and Long-term DurabilityAnother noteworthy feature of Swivel Head technology is its commitment to environmental sustainability. The company behind this innovation emphasizes the use of eco-friendly materials and manufacturing processes. By investing in furniture that incorporates Swivel Head technology, companies can demonstrate their dedication to environmental responsibility while simultaneously benefiting from the long-term durability and reliability of the product.Paragraph 7: Broad Industry Recognition and Customer FeedbackThe success of Swivel Head technology speaks for itself. Since its introduction to the market, it has received widespread recognition from renowned ergonomic experts and organizations across various industries. Furthermore, customer feedback has been overwhelmingly positive, with users reporting reduced discomfort, increased productivity, and improved overall well-being.Conclusion: A Revolution in ErgonomicsIn today's fast-paced and demanding work environments, ensuring the comfort and health of employees is crucial. Swivel Head technology offers a game-changing solution that not only enhances ergonomic support but also contributes to improved productivity and employee satisfaction. As more companies recognize the importance of investing in ergonomic design, Swivel Head technology becomes an indispensable tool towards fostering a healthier and more efficient workplace.

Durable Stainless Steel Corrugated Sheet for Various Applications

Stainless Steel Corrugated Sheet, an essential material in the construction, automotive, and industrial sectors, has gained significant popularity in recent years due to its durability, strength, and aesthetic appeal. This versatile material is commonly used for roofing, siding, and interior decoration, making it an integral part of countless projects around the world. With a wide range of applications and benefits, it has become a staple in the construction and manufacturing industries.In the competitive market of stainless steel production, {Company Name} has emerged as a leading manufacturer of high-quality corrugated sheets. The company has built a reputation for delivering top-notch products that meet the highest standards of quality, performance, and reliability. With state-of-the-art facilities and a strong commitment to innovation, {Company Name} has positioned itself as a trusted provider of stainless steel corrugated sheets for various industries.In addition to producing standard stainless steel corrugated sheets, {Company Name} offers custom solutions to meet specific project requirements. Whether it's a unique design, a specific thickness, or a special finish, the company has the capabilities to tailor its products to meet the individual needs of its customers. This level of flexibility and customization sets {Company Name} apart from its competitors and has earned the trust and loyalty of countless clients across the globe.One of the key advantages of stainless steel corrugated sheets is their exceptional strength and durability. {Company Name}'s products are engineered to withstand the harshest environmental conditions, including extreme temperatures, heavy loads, and corrosive elements. This makes them an ideal choice for outdoor applications such as roofing and siding, where protection against the elements is essential. Additionally, stainless steel is resistant to rust and corrosion, ensuring that it maintains its pristine appearance and structural integrity over time.Furthermore, stainless steel corrugated sheets offer an attractive and modern aesthetic that enhances the visual appeal of any project. Whether used for architectural accents, interior design elements, or exterior cladding, these sheets add a touch of sophistication and elegance to any space. Their sleek, clean lines and reflective surface create a contemporary look that is both timeless and versatile. {Company Name} understands the importance of aesthetics in design and strives to produce stainless steel corrugated sheets that enhance the overall appearance of a wide range of applications.In the realm of sustainability and environmental responsibility, stainless steel is a highly favorable choice. It is 100% recyclable, making it an eco-friendly option for construction and manufacturing projects. {Company Name} is committed to sustainable practices and takes pride in offering a product that not only meets the demands of modern design and construction, but also aligns with the principles of environmental stewardship. By choosing stainless steel corrugated sheets from {Company Name}, customers can contribute to the promotion of green building and manufacturing practices.With a dedication to excellence and a focus on customer satisfaction, {Company Name} has solidified its position as a leader in the stainless steel industry. Its commitment to quality, innovation, and sustainability sets it apart from its competitors and has earned it a strong reputation among clients and partners alike. As the demand for stainless steel corrugated sheets continues to rise, {Company Name} remains at the forefront of the market, delivering products that meet the highest standards of performance, durability, and aesthetics.

New Study Findings Show Benefits of Raised Rib Technology

Raised Rib Launches Innovative Product Line for Sustainable Agriculture{Company} is excited to announce the launch of its new product line, Raised Rib, designed to revolutionize sustainable agriculture practices. Raised Rib is a sustainable agriculture technology company that focuses on developing solutions to improve crop yields and soil health while reducing environmental impact.The new product line from Raised Rib offers innovative solutions for improving soil structure, water retention, and nutrient availability, ultimately leading to higher crop yields and more sustainable farming practices. The launch of these products comes at a crucial time as the agricultural industry faces increasing pressure to adopt more sustainable practices to address environmental concerns and meet growing food demand.One of the key products in the Raised Rib line is the patented Ribbed Soil Mat, a unique material designed to be placed beneath the soil to provide structural support and increase water retention. The Ribbed Soil Mat is made from a biodegradable material that decomposes over time, leaving behind improved soil structure and increased water-holding capacity. This innovative product has been shown to significantly improve crop growth and reduce the need for irrigation, contributing to more sustainable water use in agriculture.In addition to the Ribbed Soil Mat, Raised Rib has also developed a range of soil amendments and fertilizers specifically formulated to improve nutrient availability in the soil. These products are designed to work in harmony with the Ribbed Soil Mat to create an optimal growing environment for crops, leading to healthier plants and higher yields. The company has conducted extensive research and field trials to validate the effectiveness of these products and has seen promising results in improving soil health and crop productivity.Raised Rib is committed to sustainable agriculture practices and is dedicated to creating solutions that benefit both farmers and the environment. The company's products are designed with a focus on environmental sustainability, using biodegradable materials and reducing the need for chemical inputs. By improving soil health and crop yields, Raised Rib aims to contribute to a more sustainable and resilient food system."We are thrilled to introduce our new product line, Raised Rib, which has the potential to transform the way we approach sustainable agriculture," said John Smith, CEO of {Company}. "Our team has worked tirelessly to develop these innovative solutions, and we are excited to see the positive impact they can have on both farmers and the environment."In addition to developing sustainable agriculture products, Raised Rib is also committed to education and outreach to promote the adoption of more sustainable farming practices. The company offers training and resources to help farmers integrate their products into their existing practices and maximize the benefits for their crops and the environment.The launch of the Raised Rib product line represents a significant step forward in the effort to promote sustainable agriculture and improve food security. By providing innovative solutions for improving soil health and crop productivity, Raised Rib is poised to make a meaningful impact on the agricultural industry and contribute to a more sustainable future.With the launch of the Raised Rib product line, {Company} is demonstrating its commitment to innovation and sustainability in agriculture. The company's dedication to developing products that improve soil health, increase crop yields, and reduce environmental impact is a testament to its vision for a more sustainable and resilient food system. As the agricultural industry continues to evolve, Raised Rib is positioned to play a key role in driving positive change and creating a more sustainable future for farming.

New technology allows users to easily create and manage race tracks

Corner Tracks, a leading provider of innovative track solutions for heavy-duty machinery, has recently announced the launch of their latest product line designed to revolutionize the construction and mining industries.With over 20 years of experience in the industry, Corner Tracks has established a reputation for delivering high-quality, durable track systems that improve the performance and efficiency of heavy equipment. The company's commitment to innovation and continuous improvement has led to the development of their newest line of track solutions, which are set to set new standards in the industry.The new product line incorporates cutting-edge technology and advanced materials to deliver superior durability and performance in the most challenging working environments. The tracks are designed to withstand the rigors of construction and mining operations, providing reliable traction and stability to heavy equipment such as excavators, bulldozers, and loaders.One of the key features of the new product line is its advanced tread design, which has been engineered to provide maximum grip and traction in harsh terrain. This innovative tread pattern allows heavy machinery to operate more efficiently, reducing slippage and improving overall productivity on the job site.In addition, the new track solutions also feature a reinforced steel core and abrasion-resistant rubber compounds, ensuring long-lasting durability and minimal downtime for equipment maintenance. This robust construction allows the tracks to withstand heavy loads and extreme conditions, providing operators with peace of mind and confidence in their equipment's performance.Furthermore, the new track solutions from Corner Tracks are designed to be easy to install and maintain, minimizing downtime and maximizing productivity for construction and mining operations. The company's commitment to customer satisfaction is reflected in the user-friendly design of their products, which are engineered to deliver exceptional performance with minimal effort and maintenance.As part of the launch of their new product line, Corner Tracks is also offering comprehensive support and service options for their customers. Trained technicians are available to provide installation assistance and ongoing maintenance support, ensuring that customers can maximize the lifespan and performance of their track solutions."We are excited to introduce our latest line of track solutions to the construction and mining industries," said a spokesperson for Corner Tracks. "These new products demonstrate our ongoing commitment to innovation and excellence, and we are confident that they will deliver exceptional performance and value to our customers."With their dedication to quality, innovation, and customer satisfaction, Corner Tracks continues to be a trusted partner for heavy equipment operators in the construction and mining industries. The launch of their new product line is set to further solidify their position as a leading provider of track solutions, setting new standards for performance, durability, and reliability in the industry.

Quality Machined Sprockets: A Classic Addition to Your Machinery

Classic Sprockets, a leading manufacturer of precision machined sprockets, has recently announced the launch of a new line of sprockets that are set to revolutionize the industry. With a focus on quality, reliability, and innovation, Classic Sprockets has been providing high-quality sprockets to a wide range of industries for over 30 years.Founded in 1989, Classic Sprockets has grown to become one of the most trusted names in the industry. The company has built a reputation for excellence through its commitment to producing sprockets that meet the highest standards of quality and performance. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, Classic Sprockets is able to deliver sprockets that are consistently reliable and durable.The new line of sprockets from Classic Sprockets is the result of years of research and development. The company has invested heavily in the latest manufacturing technologies and production processes to ensure that its sprockets are at the forefront of innovation. The new sprockets incorporate advanced materials and design features that offer improved performance and durability compared to traditional sprockets.One of the key features of the new line of sprockets is their precision machined construction. Classic Sprockets has invested in the latest CNC machining equipment to produce sprockets that are crafted with unparalleled accuracy and consistency. This ensures that the sprockets deliver smooth and efficient performance while minimizing wear and tear on the machinery they are used in.In addition to their precision machined construction, the new line of sprockets also incorporates advanced surface treatments to enhance their durability and longevity. Classic Sprockets has developed a proprietary coating process that provides superior protection against corrosion and abrasion, ensuring that the sprockets can withstand the harshest operating conditions.Furthermore, the new line of sprockets is designed to be highly versatile and adaptable to a wide range of applications. Whether it's for use in industrial machinery, agricultural equipment, or automotive systems, the sprockets from Classic Sprockets are engineered to deliver reliable performance across diverse environments and operating conditions."We are incredibly proud to introduce our new line of sprockets to the market," said John Smith, CEO of Classic Sprockets. "Our team has put in a tremendous amount of effort to develop sprockets that not only meet but exceed the expectations of our customers. We believe these sprockets will set a new standard for quality and performance in the industry."Classic Sprockets has already begun delivering the new line of sprockets to its customers, who have expressed great excitement about the enhanced performance and reliability they provide. With the launch of this new line of sprockets, Classic Sprockets has once again demonstrated its commitment to innovation and excellence in the field of precision machined sprockets.As the industry continues to evolve and demand for high-quality sprockets grows, Classic Sprockets is well-positioned to lead the way with its new line of sprockets. With a strong focus on quality, reliability, and innovation, the company is set to continue its legacy of delivering sprockets that meet the highest standards of performance and durability.

Different Types of Food Packaging Machines: A Comprehensive Guide

When it comes to efficiently packaging food products, the use of advanced food packaging machines has become essential for companies in the food industry. These machines not only help in increasing efficiency and productivity but also ensure the safety and quality of the packaged food products. There are various types of food packaging machines available in the market, each designed to cater to specific packaging needs. Some of the most common types of food packaging machines include the following:1. Filling Machines: Filling machines are used to accurately fill containers with food products such as liquids, powders, and granules. These machines can be used for a wide range of packaging formats including bottles, cans, pouches, and jars.2. Sealing Machines: Sealing machines are used to create airtight seals on the packaging of food products. These machines can use various sealing methods such as heat sealing, induction sealing, and vacuum sealing, depending on the type of packaging material being used.3. Labeling Machines: Labeling machines are used to apply labels on food packaging containers. These machines can handle various types of labeling such as wrap-around labels, front and back labels, and top labels.4. Wrapping Machines: Wrapping machines are used to wrap food products in packaging materials such as plastic film, aluminum foil, and paper. These machines are commonly used for packaging items such as candies, chocolates, and snack bars.5. Capping Machines: Capping machines are used to securely cap bottles and containers with lids or closures. These machines can handle various types of caps including screw caps, snap caps, and press-on caps.6. Vacuum Packaging Machines: Vacuum packaging machines are used to remove air from the packaging of food products before sealing them. This helps in extending the shelf life of the food products and preserving their freshness.7. Thermoforming Machines: Thermoforming machines are used to create packaging containers from rolls of packaging material. These machines can produce a wide range of packaging formats such as trays, blister packs, and clamshells.8. Coding and Marking Machines: Coding and marking machines are used to print date codes, batch numbers, and other important information on the packaging of food products. These machines help in ensuring traceability and compliance with labeling regulations.{Company name} is a leading manufacturer of food packaging machines, offering a comprehensive range of solutions to meet the diverse needs of the food industry. With a strong focus on innovation and technology, {Company name} has been at the forefront of developing advanced packaging machines that not only enhance efficiency but also ensure the quality and safety of packaged food products.The company's range of food packaging machines includes filling machines, sealing machines, labeling machines, wrapping machines, capping machines, vacuum packaging machines, thermoforming machines, and coding and marking machines. These machines are designed to meet the specific requirements of different types of food products and packaging formats, ensuring that food manufacturers can achieve optimal packaging results.{Company name} takes pride in its commitment to customer satisfaction, offering reliable and efficient food packaging machines that are backed by comprehensive technical support and after-sales service. With a strong global presence, the company has established a solid reputation for its high-quality packaging solutions and has become a trusted partner for food manufacturers worldwide.In conclusion, the use of advanced food packaging machines is crucial for ensuring the efficiency, safety, and quality of packaged food products. With a wide range of packaging machines available, food manufacturers can choose the right solutions to meet their specific packaging needs, ultimately contributing to the success of their business. As a leading manufacturer of food packaging machines, {Company name} continues to be a driving force in the evolution of food packaging technology, helping food manufacturers stay ahead in a competitive market.

Durable and Versatile Plastic Belt for Conveyors: A Game-Changer in Material Handling

The plastic belt for conveyor, a critical component in many industries, has long been a crucial element in the transportation of goods and materials. With the advancement in technology and the increasing demand for efficiency, the need for a reliable and durable plastic belt for conveyor has become even more pronounced. This is where the {company name} comes in.{Company name} is a renowned manufacturer and supplier of high-quality plastic belts for conveyors. With their dedication to innovation and excellence, they have established themselves as a leader in the industry. Their commitment to providing top-notch products and exceptional customer service has earned them a solid reputation among their clients.The plastic belt for conveyor offered by {company name} is designed to meet the specific needs of various industries, including food processing, packaging, automotive, and more. The belts are made from high-quality materials that are resistant to wear and tear, ensuring long-lasting performance and reliability. Moreover, they are available in a variety of sizes and configurations to accommodate different conveyor systems.One of the key features of the plastic belt for conveyor from {company name} is its exceptional durability. The belts are engineered to withstand heavy loads and harsh operating conditions, making them ideal for demanding applications. They are also designed to resist corrosion and abrasion, ensuring minimal maintenance and downtime for the conveyor system.In addition to their durability, the plastic belts offered by {company name} are designed for easy installation and maintenance. Their innovative design allows for quick and hassle-free installation, reducing downtime and labor costs. Furthermore, the belts are easy to clean and sanitize, making them suitable for industries with strict hygiene and sanitation requirements.With a strong focus on customer satisfaction, {company name} provides comprehensive support and service for their products. Their team of experts is dedicated to assisting customers with selecting the right belt for their specific application, offering technical advice, and providing after-sales support. This commitment to customer service has earned {company name} a loyal and satisfied customer base.In response to the increasing demand for sustainable and environmentally friendly solutions, {company name} has also developed a range of plastic belts made from recycled materials. These eco-friendly belts not only contribute to reducing waste and conserving resources but also perform just as well as their non-recycled counterparts. This initiative highlights {company name}'s commitment to environmental responsibility and sustainability.As a testament to their excellence in manufacturing, {company name} has been recognized with various certifications and accolades for their commitment to quality and performance. Their adherence to international standards and best practices ensures that their products consistently meet and exceed the expectations of their customers.In conclusion, the plastic belt for conveyor offered by {company name} is a testament to their commitment to excellence and innovation. With a focus on durability, performance, and customer satisfaction, {company name} has established itself as a trusted partner for industries that rely on efficient and reliable conveyor systems. As they continue to push the boundaries of what is possible, {company name} is poised to remain a leader in the industry for years to come.

Durable Plastic Conveyor Belt for Industrial Use

Plastic Conveyor Belt: A Game-Changer in the Material Handling IndustryIn the fast-paced and ever-evolving world of material handling, the use of plastic conveyor belts has revolutionized the way goods are transported and processed. These innovative belts, which are designed to move materials from one place to another, have become an essential part of many industries, including manufacturing, distribution, and packaging.One of the leading companies in the production of plastic conveyor belts is [remove brand name]. With a strong focus on quality, innovation, and customer satisfaction, the company has carved a niche for itself in the material handling industry. Their commitment to excellence has earned them a reputation as a reliable and trusted supplier of conveyor belts to businesses around the world.The use of plastic conveyor belts offers numerous advantages over traditional material handling methods. These belts are lightweight, durable, and flexible, making them ideal for a wide range of applications. In addition, they can be easily customized to fit the specific needs of a business, whether it requires a straight, curved, or inclined conveyor belt.Furthermore, plastic conveyor belts are easy to clean and maintain, which helps to ensure a hygienic and safe working environment. This is particularly important in industries such as food processing and pharmaceuticals, where cleanliness is a top priority.Another significant benefit of plastic conveyor belts is their ability to handle a variety of materials, including small, delicate items, as well as heavy, bulky goods. This versatility makes them a versatile solution for businesses with diverse material handling needs.In addition to their practical advantages, plastic conveyor belts are also environmentally friendly. Unlike traditional conveyor belts, which are often made from rubber or metal, plastic belts are fully recyclable, reducing the environmental impact of material handling operations.[Remove brand name] has been at the forefront of innovation in the plastic conveyor belt industry, constantly pushing the boundaries of what is possible. Their research and development team is continuously working on new technologies and materials to improve the performance and efficiency of their conveyor belts.One of their latest developments is the use of advanced polymer blends to increase the durability and longevity of their belts. This has resulted in conveyor belts that can withstand heavy loads and harsh operating conditions, without compromising on flexibility and ease of use.Furthermore, the company has introduced innovative tracking and guiding systems that ensure the smooth and precise movement of materials along the conveyor belt. This has significantly reduced the risk of jams and blockages, resulting in improved productivity and reduced downtime for businesses using their conveyor belts.The commitment to innovation and excellence is reflected in [remove brand name]'s dedication to customer satisfaction. They work closely with their clients to understand their specific material handling needs and provide tailored solutions that meet and exceed their expectations.The company's customer service team is known for its responsiveness and reliability, ensuring that businesses can rely on their conveyor belts to keep their operations running smoothly at all times.In conclusion, plastic conveyor belts have become an indispensable tool in the material handling industry, and [remove brand name] has been at the forefront of this revolution. Their commitment to quality, innovation, and customer satisfaction has made them a trusted partner for businesses around the world. With their continued dedication to pushing the boundaries of what is possible, it is clear that plastic conveyor belts will continue to shape the future of material handling for many years to come.

Top Options for 4 Inch Square Tubing End Caps Revealed in Latest News

Title: Leading Manufacturer Introduces Innovative 4 Inch Square Tubing End Caps to the MarketIntroduction (97 words):In a bid to redefine industry standards, a renowned manufacturer, with an impressive track record spanning several decades, is proud to introduce its latest innovation - an exceptional line of 4 Inch Square Tubing End Caps. Combining cutting-edge technology with expert craftsmanship, these end caps mark a significant milestone in the company's tradition of creating high-quality solutions for various industries. With a commitment to providing reliable and durable products, the company has once again demonstrated its dedication to meeting customer needs.Paragraph 1 (96 words):As a leading manufacturer in the market, the company has diligently researched and developed a superior line of 4-inch square tubing end caps. These specialized end caps are meticulously engineered to provide unmatched protection and durability for a wide range of applications. Whether utilized in construction, storage, or other industrial applications, these end caps ensure optimal performance, fitting seamlessly into square tubing of various dimensions. The company's innovative designs take into account the versatile requirements of different industries, offering a solution that enhances productivity and safety.Paragraph 2 (106 words):One of the key features that sets these 4-inch square tubing end caps apart is their exceptional quality. Crafted from premium-grade materials, these end caps possess remarkable resistance to external factors such as extreme weather conditions, corrosion, and impact. By employing a robust manufacturing process, the company guarantees longevity and structural integrity, ensuring these end caps withstand even the harshest environments. Additionally, the user-friendly design facilitates easy installation, reducing downtime and enhancing operational efficiency. Consequently, customers can rely on these end caps to protect their square tubing investments, significantly extending their lifespan and reducing maintenance costs in the long run.Paragraph 3 (112 words):Furthermore, the company's commitment to sustainability is evident in the eco-conscious manufacturing processes employed during the production of these 4-inch square tubing end caps. By using environmentally friendly materials and implementing green initiatives, the manufacturer aims to minimize its carbon footprint without compromising on product quality. This dedication to responsible manufacturing aligns with the company's broader vision of contributing positively to the industry and society by offering sustainable and long-lasting solutions. Customers can confidently partner with the company knowing they are investing in products that are not only durable but also manufactured with a strong emphasis on environmental stewardship.Paragraph 4 (129 words):To ensure customer satisfaction, the 4-inch square tubing end caps undergo strict quality control measures throughout the production process. Thorough testing and inspection are conducted to guarantee compliance with the highest industry standards. Moreover, the manufacturer's commitment to continuous improvement ensures that these end caps remain at the forefront of innovation. The company's research and development teams continuously explore new materials, designs, and techniques to enhance the performance and functionality of their products. By consistently pushing the boundaries of what is possible, the manufacturer brings innovative solutions that cater to the evolving needs of various industries across the globe.Conclusion (100 words):With the introduction of the 4-inch square tubing end caps, this reputable manufacturer solidifies its position as an industry leader. By combining cutting-edge technology, rigorous quality control measures, and a commitment to sustainability, the company offers a truly exceptional product that meets the demands of diverse industries. These end caps serve as a testament to both the manufacturer's expertise and its unwavering dedication to customer satisfaction. As the industry adapts to new challenges and requirements, this manufacturer continues to pave the way for innovative solutions that redefine industry standards, revolutionizing the use and protection of square tubing.

Durable Plastic Plugs for Square Tubing: The Perfect Fit

Plastic Plugs For Square Tubing - A New Innovation From Leading Manufacturer[Company Name] is proud to introduce a new line of plastic plugs for square tubing that will revolutionize the industry. These innovative plugs are designed to fit securely into square tubing, providing a clean and professional finish while also protecting the tubing from damage.With over 20 years of experience in the manufacturing industry, [Company Name] has a proven track record of delivering high-quality products that meet the needs of their customers. Their dedication to innovation and excellence has earned them a reputation as a leader in the industry, and their new line of plastic plugs for square tubing is no exception.These new plastic plugs are available in a wide range of sizes to fit various square tubing dimensions, making them suitable for a variety of applications. Whether used in furniture manufacturing, construction, or any other industry that relies on square tubing, these plugs offer a versatile and practical solution for finishing off tubing ends.The design of the plastic plugs ensures a tight and secure fit, preventing them from slipping out of the tubing once inserted. This not only provides a cleaner and more professional appearance but also offers added protection to the tubing, reducing the risk of damage from external elements.In addition to their functional benefits, these plastic plugs also offer aesthetic advantages. Their sleek and uniform appearance provides a polished finish to the ends of square tubing, enhancing the overall look of the finished product. Whether used in the production of tables, chairs, shelving units, or any other product that utilizes square tubing, these plugs can elevate the final appearance of the product.Furthermore, the plastic plugs are made from high-quality materials that are durable and long-lasting. This ensures that they can withstand the rigors of everyday use without deteriorating or losing their functionality. With these plugs, manufacturers and consumers can have confidence in the longevity and reliability of the finished products.[Company Name] is committed to sustainability and environmental responsibility, and their new line of plastic plugs for square tubing reflects this commitment. The plugs are made from recyclable materials, reducing their environmental impact and promoting a more sustainable manufacturing process.To further demonstrate their dedication to quality and customer satisfaction, [Company Name] stands behind their new line of plastic plugs with exceptional customer service and support. Their team of experts is available to answer any questions, provide assistance with product selection, and offer guidance on the installation and use of the plastic plugs.With their innovative design, practical benefits, and commitment to quality and sustainability, [Company Name]'s new plastic plugs for square tubing are set to become a game-changer in the industry. Manufacturers and consumers alike can now rely on these innovative plugs to deliver a clean and professional finish, while also protecting their square tubing from damage.In conclusion, [Company Name] continues to raise the bar in the manufacturing industry with the introduction of their new line of plastic plugs for square tubing. With their emphasis on innovation, excellence, and sustainability, these plugs represent the next evolution in finishing and protecting square tubing, setting a new standard for quality and reliability. As the industry looks for practical and effective solutions, [Company Name] has once again delivered a product that meets and exceeds the needs of their customers.