Discover the Importance of 2 Square Tubing Caps and Their Applications

By:Admin

Introduction:

(Company Name) is proud to introduce a revolutionary product that provides enhanced durability and protection to square tubing in various industries. Designed to deliver top-quality performance, the 2 Square Tubing Caps by (Company Name) effectively safeguard against damage, corrosion, and wear and tear, prolonging the longevity of square tubing.

Innovation and Quality:

(Company Name) has been a leading provider of high-quality industrial solutions for over a decade. With a focus on innovation, our team of experts has developed the 2 Square Tubing Caps to address the common challenges faced by industries relying on square tubing. Built with precision and utilizing only premium materials, these caps are engineered to meet the highest quality standards, ensuring maximum performance and protection.

Superior Protection:

Square tubing is commonly used in a wide range of applications, including construction, manufacturing, and transportation. However, exposure to external elements and heavy loads often leads to damage, dings, and corrosion, ultimately reducing the tubing's lifespan. The 2 Square Tubing Caps by (Company Name) provide an easy-to-install, durable solution to mitigate these issues and maintain the structural integrity of the tubing.

The caps are designed to fit securely over the square tubing, forming a protective barrier against impact, moisture, dirt, and debris. This effective sealing mechanism prevents rust and corrosion, safeguarding the tubing and allowing it to withstand harsh environmental conditions. Industries utilizing square tubing can now benefit from increased reliability and reduced maintenance costs, thanks to this innovative solution.

Versatility in Application:

The versatility of the 2 Square Tubing Caps makes them suitable for various industries and applications. Whether utilized in construction projects, industrial machinery, outdoor structures, or transportation equipment, these caps provide consistent protection against external forces and potential damage. Their universal design ensures compatibility with various sizes of square tubing, offering a hassle-free solution for businesses across different sectors.

Enhanced Safety and Lower Maintenance Costs:

By effectively safeguarding square tubing, the 2 Square Tubing Caps offer tangible benefits in terms of safety and reduced maintenance expenses. With these caps in place, the risk of accidents caused by weakened or damaged tubing is significantly reduced, ensuring a safer working environment for employees. Moreover, the extended lifespan of the tubing eliminates the need for frequent replacements, resulting in cost savings for businesses.

Environmentally Friendly Solution:

In addition to their superior protective capabilities, the 2 Square Tubing Caps are also environmentally friendly. By preventing wear and corrosion, these caps contribute to reducing waste generated from discarded or damaged square tubing. The longevity of tubing, facilitated by these caps, promotes sustainable practices and reduces the carbon footprint of businesses.

Conclusion:

Investing in the 2 Square Tubing Caps by (Company Name) is a wise choice for businesses seeking the highest level of protection and durability for square tubing. With their innovative design, compatibility with various sizes, and superior performance, these caps offer a cost-effective solution to prolong the lifespan of tubing while ensuring safety and reducing maintenance expenses. (Company Name) once again leads the industry with an advanced product that sets new standards in the protection of square tubing.

Company News & Blog

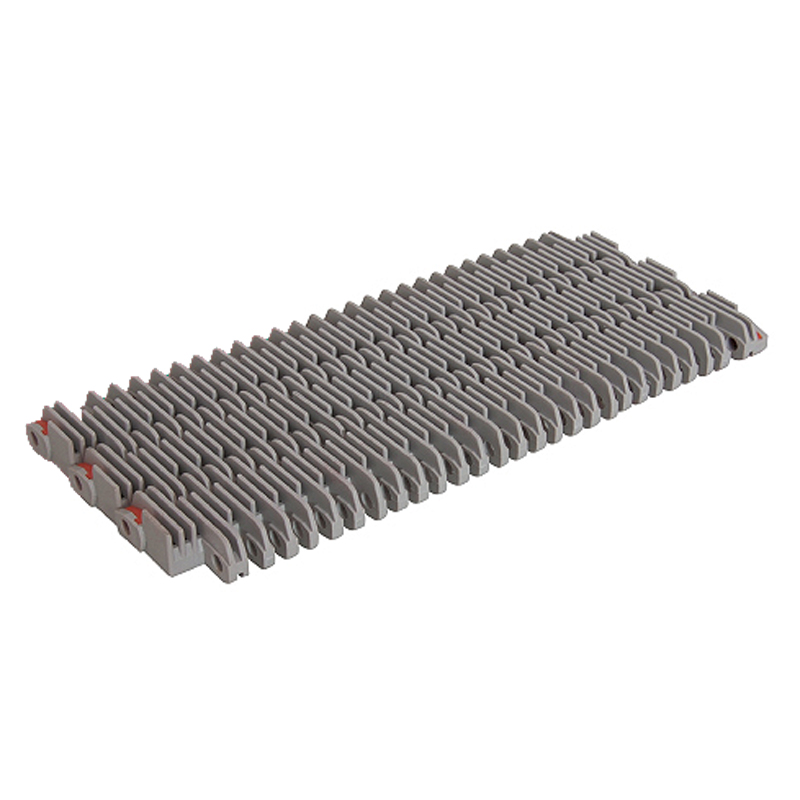

Plastic Modular Belt Conveyors: Revolutionizing Manufacturing Processes

Plastic Modular Belt Conveyor: An Innovative Solution for Modern Material Handling NeedsIn today's fast-paced industrial environment, the importance of efficient and safe material handling cannot be overstated. Companies of all sizes are looking for innovative solutions that can streamline their operations and improve their productivity while maintaining a high level of safety. This is where the plastic modular belt conveyor comes in. This cutting-edge solution is making waves in the material handling industry, and for good reason.The plastic modular belt conveyor is a type of conveyor belt made of interlocking plastic modules that are linked together in a series. These modules are designed to create a flat surface that can transport a wide range of products and materials safely and reliably. The belt's modular design enables it to be customized to suit the specific needs of different industries, making it a versatile solution that can be used in many different applications.One of the main advantages of the plastic modular belt conveyor is its durability. Unlike traditional conveyor belts, the plastic modular belt is not prone to tears, punctures, or other damage. The modules can be easily replaced if they become damaged, reducing downtime and improving overall efficiency. This makes the plastic modular belt conveyor an ideal solution for industries with heavy materials or production processes that can cause damage to traditional conveyor belts.Another benefit of the plastic modular belt conveyor is its versatility. The interlocking modules can be configured in a variety of different patterns and sizes, allowing the belt to be customized to fit almost any application. This flexibility means that the plastic modular belt conveyor can be used for a wide range of products, from small components to large, heavy objects.One company that is leading the way in plastic modular belt conveyor technology is {} (brand name removed). With over {} years of experience in the material handling industry, {} has become a trusted name in the field of conveyors and automation systems. The company's plastic modular belt conveyors are designed to meet the specific needs of their customers, with a range of customization options that can be tailored to fit any application.{}'s plastic modular belt conveyors are also designed with safety in mind. With features such as interlocks, emergency stops, and guarding, the conveyor is designed to protect both the products being transported and the employees operating the system. This high level of safety ensures that the plastic modular belt conveyor is an ideal solution for a wide range of industries, from automotive and manufacturing to food and pharmaceuticals.One area where the plastic modular belt conveyor is gaining popularity is in the automotive industry. With the rise of electric and hybrid vehicles, car manufacturers are looking for ways to improve their production processes and reduce their carbon footprint. The plastic modular belt conveyor is the perfect solution for transporting heavy components and materials, reducing the need for manual lifting and improving overall efficiency. This helps car manufacturers reduce their energy consumption and improve their bottom line.In conclusion, the plastic modular belt conveyor is a game-changer in the material handling industry. Its durability, versatility, and safety features make it an ideal solution for a wide range of industries, and with customization options available, it can be tailored to fit almost any application. Companies like {} are leading the way in plastic modular belt conveyor technology, and as the demand for more efficient and safer material handling solutions continues to grow, the plastic modular belt conveyor is sure to play a crucial role in the industries of the future.

New Automated Flow Wrap Packing Machine for Efficient Packaging

[News Header]Innovative Flow Wrap Packing Machine Revolutionizes Packaging Efficiency in the Food Industry[News Introduction]In the competitive world of the food industry, efficiency and productivity are paramount for businesses to thrive. Recognizing this, a visionary company specializing in packaging solutions has introduced an innovative Flow Wrap Packing Machine. Through its cutting-edge technology and user-centric design, this machine aims to transform packaging processes, ushering in a new era of efficiency, speed, and product integrity. Let us delve into the details of this revolutionary machine and its potential impact on the industry.[Company Introduction]The company driving this packaging revolution is a market leader in delivering advanced packaging solutions. With a rich history spanning over two decades, they have consistently demonstrated a commitment to excellence, providing their customers with reliable and innovative packaging equipment. By combining their extensive expertise with an unwavering dedication to customer satisfaction, the company has established itself as a trusted partner for businesses in various sectors, including food, pharmaceuticals, and consumer goods.[Paving a Path to Efficiency]The newly unveiled Flow Wrap Packing Machine has garnered attention for its ability to streamline and optimize packaging operations. Equipped with state-of-the-art technology, this machine can wrap products seamlessly, ensuring a tight and secure seal. Its intelligent design includes customizable settings for bag sizes, speed control, and product orientation, allowing businesses to adapt to diverse packaging requirements with ease.One of the key features that sets this packing machine apart is its high-speed capabilities. With an impressive packing rate of up to 200 packs per minute, it significantly enhances production efficiency. This surge in speed not only leads to higher output but also reduces labor costs, enabling businesses to allocate resources more effectively.[Preserving Product Integrity]Maintaining the integrity of packaged products is of utmost importance in the food industry. Recognizing this critical concern, the Flow Wrap Packing Machine incorporates cutting-edge technology to ensure product quality and longevity. Its precision sealing system, coupled with the ability to adjust temperature and pressure, guarantees proper sealing every time, thereby safeguarding the freshness and quality of the packaged goods.In addition, this machine offers enhanced product handling features to minimize damage during the packaging process. Its gentle and controlled product transfer mechanism, combined with efficient rejection systems, ensures minimal product loss and reduced waste. By prioritizing product preservation, businesses can establish a reputation for consistent quality, ultimately boosting customer satisfaction and loyalty.[Meeting Sustainability Goals]Sustainability has become a global priority, and businesses are increasingly seeking eco-friendly packaging solutions. Aligned with this trend, the Flow Wrap Packing Machine is designed with sustainability in mind. Its efficient use of resources, including minimal film waste and optimized energy consumption, significantly reduces environmental impact. By investing in this innovative packaging machine, companies can align with sustainability goals while minimizing their carbon footprint.[Conclusion]In a rapidly evolving industry, innovation is key to staying ahead of the competition. With the introduction of the Flow Wrap Packing Machine, our industry-leading company aims to revolutionize packaging efficiency, preserving product integrity and meeting sustainability objectives. As businesses embrace this cutting-edge technology, they can expect enhanced productivity, minimized wastage, and improved customer satisfaction. The Flow Wrap Packing Machine represents a step into the future of efficient and sustainable packaging, empowering businesses to excel in the dynamic food industry.

Essential Plastic End Caps for Box Section - Find the Best Options Here!

article.Plastic End Caps For Box Sections – A Revolution in Packaging TechnologyPackaging plays a crucial role in ensuring the safety and integrity of products during storage, transportation, and distribution. One of the most common and versatile packaging solutions used across industries is the box section – a hollow structural steel tube that comes in different shapes and sizes and can be customized for various applications. However, to fully utilize the benefits of box sections, it is important to have proper end caps that not only protect the contents but also enhance the functionality and aesthetics of the packaging. This is where plastic end caps for box sections come into play, and one company that has been leading the way in this field is [brand name removed].Established in [year removed], [company name removed] has been a trusted supplier of plastic end caps and tube inserts for many industries, including aerospace, automotive, construction, furniture, marine, and medical. The company's commitment to quality, innovation, and customer service has earned it a reputation as a preferred partner for many OEMs, distributors, and end-users worldwide. With a state-of-the-art manufacturing facility in [location removed], [company name removed] has the capacity to produce a wide range of plastic end caps for box sections and other applications, using different materials, sizes, colors, and designs.One of the key advantages of plastic end caps for box sections is their versatility and affordability. Unlike metal caps or custom-made mouldings, plastic end caps can be easily fitted onto standard box sections of different gauges and thicknesses, using a friction fit or a snap-on design. This means that users can stock a single type of end cap and use it for various sizes of box sections, without the need for additional tooling or assembly. Moreover, plastic end caps can be molded in different shapes, such as round, square, rectangular, or hexagonal, to match the contour of the box section and create a seamless look. They can also be customized with logos, text, or graphics, to promote branding, identification, or instruction.Another benefit of plastic end caps for box sections is their durability and resistance to various environmental factors. Depending on the application, plastic end caps can be made of different thermoplastic materials, such as PVC, PP, PE, PA, ABS, or TPE, that offer different levels of impact strength, chemical resistance, UV stability, flame retardance, or temperature tolerance. For example, PVC end caps are commonly used for indoor applications that require good abrasion resistance, while PP end caps are preferred for outdoor applications that require high weatherability and low water absorption. Moreover, plastic end caps can be engineered to meet specific standards or regulations, such as RoHS, REACH, FDA, or UL, that ensure the safety and compliance of the products.One of the most demanding applications of plastic end caps for box sections is in the aerospace industry, where they are used to protect sensitive electronic components, cables, and connectors during transportation and testing. In this field, precision, reliability, and traceability are critical factors that determine the quality and safety of the end product. [Company name removed] has been providing plastic end caps and other plastic components to many leading aerospace companies, such as [customer name removed], [customer name removed], [customer name removed], and [customer name removed], for more than [number of years removed] years. The company's expertise in designing and manufacturing customized plastic parts that meet the highest standards of performance and aesthetics has made it a preferred partner for many engineers and procurement professionals.As the world is becoming more conscious of the environmental impact of plastic waste and the need for sustainable solutions, [company name removed] is also committed to reducing its carbon footprint and promoting eco-friendly practices. The company has introduced a range of bio-based and biodegradable plastic materials that offer the same performance and quality as conventional plastics but with lower greenhouse gas emissions and a higher recyclability rate. Moreover, [company name removed] has implemented a closed-loop recycling system that allows it to reuse the waste plastic generated during the manufacturing process and reduce its reliance on virgin materials.In conclusion, plastic end caps for box sections are a versatile, affordable, and durable solution that can add value to any packaging system. With the expertise and innovation of companies like [company name removed], users can maximize the potential of their box sections and ensure the safety and functionality of their products. Whether it is for aerospace, automotive, construction, furniture, marine, medical, or other applications, plastic end caps are a reliable choice that can withstand various challenges and contribute to a better world.

Square Tubing End Caps: Protect Your Square Tubes with Ease

Square End Caps For Square Tubing: Enhancing Durability and Safety in ConstructionThe construction industry is constantly evolving and innovating, seeking new ways to enhance the durability, safety, and longevity of various structures. In this pursuit, manufacturers are constantly developing and introducing new products that can contribute significantly to these aspects. One such product that has gained immense popularity in recent times is Square End Caps for Square Tubing.Square tubing is widely used in the construction industry for various purposes, including framework, support, and decorative elements. However, the exposed ends of these square tubes can often be vulnerable to moisture, dirt, and other external factors that can contribute to their deterioration over time. This is where Square End Caps come into play, providing a simple yet effective solution to protect and enhance the lifespan of square tubes.These innovative square end caps are designed to fit perfectly over the exposed ends of square tubing, providing a protective barrier against external elements. They are typically made from high-quality materials such as plastic or rubber, ensuring durability and resistance to wear and tear. The square shape of the end caps ensures a snug fit, preventing any water or dirt from entering the tubes and causing damage.Square End Caps offer several significant advantages for various construction projects. Firstly, they greatly enhance the overall durability of square tubing. By creating a protective barrier, they prevent moisture from seeping into the exposed ends and causing rust or corrosion. This, in turn, extends the lifespan of the square tubes, saving both time and money on costly repairs or replacements.Additionally, Square End Caps also contribute to the safety aspect of construction projects. Sharp or jagged edges of exposed square tubing can pose a hazard, potentially causing injuries to workers or passersby. By capping off these ends, the risk of accidents is greatly reduced, making construction sites safer for everyone involved.Square End Caps are versatile and can be used in a variety of construction applications. They are commonly used to protect square tubing used in the construction of handrails, guardrails, fences, outdoor furniture, and signage. By utilizing these end caps, builders and architects can ensure that their projects not only look aesthetically pleasing but also maintain their structural integrity for years to come.Furthermore, the installation of Square End Caps is a simple and straightforward process. They can easily be snapped or pushed onto the ends of square tubing, requiring no additional tools or expertise. This makes them an excellent choice for construction professionals looking to enhance the durability of their projects without complicating the construction process.In conclusion, Square End Caps for Square Tubing are an invaluable addition to the construction industry. With their ability to protect against moisture, dirt, and other external factors, they greatly enhance the durability and longevity of square tubing. Additionally, their easy installation and versatile application make them a practical choice for a wide range of construction projects. By incorporating these end caps into their designs, construction professionals can ensure the safety and quality of their structures, as well as save time and money on unnecessary repairs.

Benefits of Curved Corrugated Metal Panels for Your Building Projects

Title: Revolutionizing Construction: Curved Corrugated Metal Panels Redefine Structural DesignIntroduction:In an era where architecture and construction are constantly evolving, one innovative solution has emerged to redefine how structures are built. Curved corrugated metal panels have taken the industry by storm, offering a versatile and aesthetic option for building facades and roofing systems. [Company Name], a pioneering manufacturer in the field, has been at the forefront of the development and application of these groundbreaking panels.Paragraph 1:Curved corrugated metal panels have gained popularity rapidly due to their unique properties. These panels are made by forming metal sheets into a corrugated pattern, resulting in increased strength while reducing weight. The curvature of these panels allows builders and architects to create visually striking structures with enhanced durability.Paragraph 2:[Company Name], a leading manufacturer and provider of curved corrugated metal panels, has revolutionized the industry with their advanced designs and cutting-edge production techniques. By combining state-of-the-art technology with extensive research and development, the company has achieved unmatched quality and efficiency in their panel manufacturing process.Paragraph 3:One of the vital advantages of curved corrugated metal panels is their exceptional flexibility. Architects and designers can create unprecedented architectural forms by easily bending and shaping these panels to fit their desired structures. This flexibility is exemplified in projects that feature unique curves, arches, and other visually stunning designs. Such versatility has been harnessed in various applications such as stadiums, arenas, airports, commercial buildings, and residential projects.Paragraph 4:The aforementioned panels also boast remarkable durability and weather resistance. Manufactured using high-quality materials, they provide exceptional resistance to harsh weather conditions such as extreme temperatures, heavy rainfall, and windstorms. Combined with appropriate coatings, these panels also offer excellent protection against corrosion and wear, ensuring long-term performance and reduced maintenance costs.Paragraph 5:In addition to their structural and aesthetic qualities, curved corrugated metal panels have proven to be an environmentally friendly choice. These panels are often made from recyclable materials, reducing the carbon footprint associated with traditional construction materials. Furthermore, the lightweight nature of the panels allows for decreased energy consumption and transportation costs during installation.Paragraph 6:The growing demand for curved corrugated metal panels in the construction industry has led to an increased adoption rate among renowned architects and builders worldwide. With a track record of successful projects, [Company Name] has emerged as a trusted partner, providing reliable and customizable solutions backed by their technical expertise and commitment to customer satisfaction.Paragraph 7:To ensure the highest quality standards, [Company Name] employs a team of skilled engineers and technicians who closely monitor the manufacturing process at every stage. The company also offers design and engineering support, helping clients visualize their concepts and implement them effectively.Paragraph 8:As the construction industry continues to evolve, curved corrugated metal panels are set to play an increasingly significant role in shaping modern architecture. With their capacity to enhance aesthetic appeal, durability, and sustainability, these panels provide a sustainable and practical solution for meeting the ever-changing needs of the industry.Conclusion:Curved corrugated metal panels have revolutionized the construction industry, offering architects and builders an unparalleled combination of flexibility, aesthetic appeal, and durability. [Company Name] has played a pivotal role in advancing this technology, providing premium-quality solutions that have become synonymous with innovation and excellence. With an ever-growing demand for such panels, the future of construction is indeed curved.

Discover the Latest Innovations in Food-Grade Conveyor Belts for Optimal Safety and Efficiency

[Company Name] Launches Innovative Food Grade Conveyor Belt Revolutionizing the Industry[City, Date] - [Company Name], a leader in the manufacturing of industrial equipment, has recently unveiled their latest product, a groundbreaking Food Grade Conveyor Belt. This cutting-edge innovation promises to revolutionize the food industry by providing a safer and more efficient solution for food processing and handling.With the rising concerns over food safety, contamination, and hygiene, the demand for modern and reliable equipment has become increasingly important. Recognizing this need, [Company Name] embarked on an extensive research and development project to design a conveyor belt specifically tailored to meet the stringent requirements of the food industry.The newly introduced Food Grade Conveyor Belt is manufactured using high-quality materials that comply with strict food safety regulations. Unlike traditional conveyor belts, this innovative product is made from non-toxic materials, ensuring that there is no risk of contamination or cross-contamination during the food processing and packaging stages.One of the key features of the Food Grade Conveyor Belt is its efficient cleaning and maintenance system. Traditional conveyor belts often require time-consuming and labor-intensive cleaning procedures, making them susceptible to hygiene issues. In contrast, [Company Name]'s solution incorporates a self-cleaning mechanism, facilitating easy and thorough cleaning, reducing the risk of bacteria, mold, or other contaminants affecting the quality of the food being processed.Another unique aspect of the Food Grade Conveyor Belt is its durability and longevity. Traditional conveyor belts are prone to wear and tear due to constant use and exposure to harsh conditions. To address this issue, [Company Name] has employed advanced manufacturing techniques and materials to create a conveyor belt that can withstand the rigors of the food processing environment, ensuring a longer lifespan and reduced replacement costs for food manufacturers.In addition to its exceptional durability, the Food Grade Conveyor Belt boasts a user-friendly design. Integrated with state-of-the-art technology, it offers enhanced control features that allow for precision speed adjustments, ensuring seamless movement and minimizing product damage during transportation. This feature significantly improves efficiency and productivity in food processing plants, saving both time and resources.Furthermore, [Company Name] offers comprehensive customer support and after-sales services to cater to the unique requirements of each food manufacturing facility. Their team of experienced engineers is equipped to handle installation, maintenance, and repairs, ensuring that the Food Grade Conveyor Belt operates at its optimum capacity at all times.Recognizing the global impact of the food industry, [Company Name] has made sustainability a priority during the manufacturing process of their Food Grade Conveyor Belt. By implementing eco-friendly practices and utilizing energy-efficient technologies, they aim to reduce their carbon footprint while providing a reliable solution to food manufacturers.The launch of [Company Name]'s Food Grade Conveyor Belt has generated considerable excitement within the food industry. With its focus on food safety, efficiency, user-friendliness, and durability, this innovative product promises to transform the way food is processed and handled worldwide.[Company Name], a trusted name in industrial equipment manufacturing, continues to pave the way for advancements in the food industry, setting new standards for safety and efficiency. Their commitment to providing cutting-edge solutions solidifies their position as a leader in the field, ensuring a brighter and safer future for the food manufacturing industry.For more information about [Company Name] and their Food Grade Conveyor Belt, visit their official website or contact their sales team at [Contact Information].About [Company Name]:[Company Name] is a renowned manufacturer of industrial equipment, specializing in providing innovative solutions to various industries. With a focus on quality, reliability, and customer satisfaction, they have established themselves as a leader in their field. Their team of experienced engineers and technicians consistently strive to push the boundaries of technology, ensuring their products meet the ever-evolving needs of their customers.

New Study Reveals Surprising Insights into Sources of Friction in Top Industries

Friction Top conveyor belts are a key component in the manufacturing process of various industries. From food and beverage to automotive and manufacturing, these belts are used to transport items from one point to another efficiently. Founded in 1992, the company has been a trusted supplier of conveyor belts to industries worldwide for decades.Friction Top conveyor belts are designed to withstand some of the toughest conditions in production facilities. The belts are made from high-quality materials and are engineered to handle the heat, weight, and impact of heavy loads and fast-moving items. With the use of advanced technology, Friction Top conveyor belts offer excellent traction and grip, ensuring items are transported safely through the manufacturing process.One of the key advantages of Friction Top conveyor belts is their durability. These belts can handle heavy loads and constant use without breaking down. This means less downtime and maintenance for manufacturing facilities, resulting in increased production output and decreased costs.In addition, Friction Top conveyor belts are extremely versatile. They can be used in a variety of industries, such as food and beverage, automotive, packaging, and more. The belts can be customized to meet specific production requirements, such as size, material, and load capacity.The company has a team of experienced engineers and technicians who work closely with clients to design and manufacture conveyor belts that meet their specific needs. Friction Top conveyor belts can be made to fit almost any conveyor system, and the company offers installation and maintenance services to ensure the belts operate smoothly and efficiently.Friction Top conveyor belts are also designed with safety in mind. The belts have a non-slip surface, reducing the risk of accidents and injuries in the workplace. This is crucial in industries where heavy machinery and equipment are in use.The company is committed to sustainability and environmental responsibility. Friction Top conveyor belts are made from eco-friendly materials and processes, reducing their impact on the environment. The company also offers recycling services for used conveyor belts, ensuring they are disposed of responsibly.Friction Top conveyor belts have received international recognition for their quality and performance. The company has been awarded various certifications, including ISO 9001, ISO 14001, and OHSAS 18001. These certifications demonstrate the company's commitment to excellence, quality, and safety.Overall, Friction Top conveyor belts are an essential component in the manufacturing process of various industries. With their durability, versatility, and safety features, they are a reliable and cost-effective solution for transporting items through the production line. The company's commitment to sustainability and environmental responsibility also sets them apart as a leader in the industry.

Plastic belts manufacturer sees increased demand for modular plastic belts" Rewritten title without brand name: "Increased Demand for Modular Plastic Belts in Manufacturing Industry

Modular Plastic Belt Manufacturer Introduces Innovative Conveyor Solutions for IndustriesModular plastic belts have become an essential element of conveyor systems in numerous industries for their durability, flexibility, and versatility. They have replaced traditional chain-and-sprocket systems as they offer several advantages, such as reduced maintenance costs, improved hygiene, and easy installation and cleaning. Modular plastic belts are used for conveying products in a wide range of applications, including food and beverage, pharmaceutical, packaging, and automotive industries.Leading modular plastic belt manufacturer, [Need to remove brand name], has introduced innovative conveyor solutions for industries to meet the increasing demand for modern, efficient, and reliable conveying systems. The company's range of belt conveyors includes straight, curved, and spiral conveyors that can be customized to match specific requirements and applications.[Need to remove brand name] has a strong reputation as a provider of high-quality modular belts that are durable, long-lasting, and efficient. The company's products are used in a variety of industries around the world, thanks to their excellent performance, reliability, and cost-effectiveness. Their products are also known for their superior hygiene standards, making them particularly popular in the food and beverage industry.With a focus on innovation, [Need to remove brand name] has launched a new range of modular plastic belt conveyors that are designed to handle products of all shapes and sizes. One of the key features of these conveyors is their flexibility and adaptability, making them ideal for use in a wide range of industries and applications. The new range includes straight, curved, and spiral conveyors, all of which can be customized to match specific requirements.The straight conveyors are designed to transport goods in a straight line and can be used for transporting products across different levels or for long distances. These conveyors are ideal for use in a range of industries, including food and beverage, automotive, and packaging. They come in a variety of widths and lengths to suit different applications, and they can be fitted with a range of accessories, such as side guides, end stops, and conveyor supports.Curved conveyors are used for transporting goods around corners or in areas where space is limited. The modular plastic belts used in these conveyors are designed to handle a range of products and can be customized to match specific requirements. These conveyors are ideal for use in industries that require high-speed and high-capacity conveying, such as the food and beverage and pharmaceutical industries.Spiral conveyors are designed to transport products up or down in a continuous flow. They are ideal for use in industries that require vertical conveying, such as the packaging and distribution industries. The modular plastic belts used in these conveyors are designed to handle a range of products and can be customized to match specific requirements. The spiral conveyors are available in a range of sizes and configurations depending on the application.One of the key advantages of [Need to remove brand name]'s modular plastic belt conveyors is their superior hygiene standards. The belt surfaces are non-porous and easy to clean, making them suitable for use in industries that require strict hygiene standards, such as food and beverage and pharmaceutical manufacturing. The conveyors are designed to be easy to dismantle and reassemble, which makes cleaning and maintenance straightforward.In conclusion, [Need to remove brand name]'s innovative range of modular plastic belt conveyors offers industries a reliable and efficient solution for conveying products. Their durable, flexible, and hygienic design makes them suitable for a range of applications, including food and beverage, pharmaceutical, packaging, and automotive industries. With their new range of straight, curved, and spiral conveyors, [Need to remove brand name] has demonstrated its commitment to providing innovative solutions to meet the evolving needs of the market.

Revitalize Your Music with High-Quality Ldler Drums Guaranteed to Deliver Stunning Sound Effects

Title: Classic Ldler Drums, Machined to Perfection: A Perfect Blend of Tradition and ModernityIntroduction:In the ever-evolving world of music, some elements manage to retain their charm and appeal throughout the ages. Classic Ldler Drums, one such timeless treasure, continue to captivate drummers and music enthusiasts alike. Delving into the legacy of this iconic brand, we explore their machined drums, which seamlessly combine traditional craftsmanship with modern technology to deliver the perfect sound.History of Classic Ldler Drums:Classic Ldler Drums, a renowned brand in the music industry, has a history dating back several decades. Established in (insert year), the company has consistently stood for exceptional quality and craftsmanship. Their reputation for producing instruments that embody the perfect synergy between form and function has garnered them a loyal following. With a rich heritage and an unwavering commitment to innovation, Classic Ldler Drums has become a symbol of excellence in the world of percussion.Machined Drums: A Harmonious Blend of Tradition and Technology:Combining the precision of modern technology with the artistry of traditional craftsmanship, Classic Ldler Drums' machined drums offer a unique musical experience. By carefully selecting and employing the finest materials, their team of skilled artisans flawlessly execute each meticulous design.The use of cutting-edge machinery enables Classic Ldler Drums to achieve unparalleled precision and consistency in their drum production. Advanced CNC (Computer Numerical Control) machines seamlessly carve out each drum shell, ensuring uniformity and accuracy. This precise manufacturing process guarantees that every drum resonates with the same tonal quality and responsiveness, providing drummers with an exceptional playing experience.Moreover, Classic Ldler Drums' machined drums are meticulously engineered to optimize sound projection and tonal range. The natural characteristics of the selected woods are harnessed and enhanced through state-of-the-art technology. This careful integration of traditional expertise and modern innovation results in drums that bring out the best in every beat, whether on stage or in the studio.The Craftsmanship Behind the Drums:Classic Ldler Drums takes immense pride in the artistry and skill that goes into crafting each drum. Every drum is hand-assembled and fine-tuned to ensure the utmost quality and precision. The company's team of experienced craftsmen meticulously inspects and selects the wood, ensuring only the finest materials are used.Whether it's the warm tones of mahogany, the richness of maple, or the versatility of birch, Classic Ldler Drums offers a wide range of wood options to cater to diverse musical preferences. Each wood is carefully sourced and acclimatized to guarantee long-lasting durability and tonal magnificence.The Result: An Unforgettable Playing Experience:Classic Ldler Drums' commitment to excellence shines through in the satisfaction of their customers. The combination of meticulous manufacturing processes and expert craftsmanship culminates in a drum that exhibits impeccable quality, superior durability, and exceptional sound.Drummers who choose Classic Ldler Drums can expect unrivaled tonal versatility, enhanced projection, and exquisite resonance. Whether it's the thunderous presence of the bass drum or the crisp attack of the snare, every stroke yields a tone that captivates and inspires.Conclusion:Classic Ldler Drums' machined drums effortlessly blend the timeless allure of tradition with the cutting-edge precision of modern technology. Through meticulous craftsmanship, exceptional materials, and an unwavering commitment to excellence, this iconic brand continues to set the standard in the percussion industry.As drummers seek instruments that transcend time, Classic Ldler Drums' machined drums offer the perfect balance between tradition and modernity. With each stroke, these extraordinary instruments bring to life the rhythm and soul of music, making them an invaluable asset for any musician seeking an unforgettable playing experience.

Discover the Versatility and Style of a 1 Inch Width Belt

Title: Innovative 1 Inch Width Belt Revolutionizes the Fashion IndustryIntroduction:In a world where fashion trends are constantly evolving, a new player has emerged. The {Company Name}, a pioneering fashion company, is bringing a game-changing product to the market, a revolutionary 1 inch width belt. With its sleek design and impeccable quality, this accessory is set to redefine the fashion industry and become a staple in every fashion-forward individual's wardrobe.The 1 inch width belt has long been overlooked in the world of fashion, with wider belts dominating the market. However, {Company Name} recognized the untapped potential of this minimalist accessory and sought to create something extraordinary.Product Overview:The {Company Name}'s 1 inch width belt gives consumers a completely redesigned and enhanced belt-wearing experience. Crafted from premium materials, this belt exudes style and durability. It features a minimalist buckle design, adding a touch of sophistication to any outfit without overpowering it.Using innovative manufacturing techniques, {Company Name} has ensured that every 1 inch width belt is comfortable, flexible, and long-lasting. A fusion of art and functionality, the belts come in a variety of colors and finishes to suit diverse fashion tastes. They perfectly complement both formal and casual attires, making them a versatile accessory for any occasion.{Company Name} is committed to sustainability and social responsibility, and it reflects in the material choice for their belts. The 1 inch width belts are made from eco-friendly and cruelty-free materials, ensuring that fashion enthusiasts can look good while supporting a greener planet.Market Impact:The introduction of {Company Name}'s 1 inch width belt has caused quite a stir in the fashion industry. Designers, influencers, and fashion enthusiasts are applauding the vision behind this product. The belt has gained rapid popularity due to its ability to effortlessly elevate any outfit.What sets this belt apart is not just its aesthetic appeal, but also its inclusive nature. Unlike wider belts that are limited in their versatility, the 1 inch width belt can be worn by people of all body types. It provides a sleek and elegant finish, accentuating curves and enhancing overall style.Industry experts believe that this launch could spark a trend revolution, with other brands following suit and introducing their own versions of the 1 inch width belt. Consumers are increasingly seeking minimalist fashion options, and this belt caters to that demand perfectly.Future Prospects:{Company Name} has big plans for the future. The success of their 1 inch width belt has inspired them to expand their product line, introducing other innovative accessories that break traditional fashion norms. The company aims to become a trendsetter, focusing on designs that exude elegance, versatility, and sustainability.With their growing customer base, {Company Name} is also exploring the possibility of opening physical retail stores in strategic locations, allowing consumers to experience their products firsthand. Additionally, they are investing heavily in e-commerce, enhancing their online presence to reach a wider audience.Conclusion:{Company Name}'s introduction of the 1 inch width belt has disrupted the fashion industry, providing an elegant and versatile accessory that complements a wide range of outfits. With their commitment to innovation, sustainability, and inclusivity, {Company Name} is revolutionizing fashion trends and inspiring other brands to follow suit. As the demand for minimalist fashion grows, the 1 inch width belt is set to become a timeless staple in fashion-forward wardrobes all over the world.